CALL US NOW

Powerful. Eco-friendly. Dependable. Energy-smart.

Insulated building products to meet all residential,

commercial, agricultural or industrial project needs.

Interlocking Radiant

Floor Heat Panel

We are building a better future.

We produce high-quality and sustainable building products that provide

customers peace of mind that their projects are built efficiently, reliably,

and with the ability to withstand even the most extreme elements of

mother nature.

As a family-owned company, we hold ourselves accountable to our SuperForm family (customers, partners, vendors, and fellow teammates) through our dedication and passion for quality, sustainability, and continuous improvement.

Products

Builders choose Superform building products because they are stronger and more reliable than the competition. Let’s take a look at some of the products that make SuperForm one of the top ICF companies.

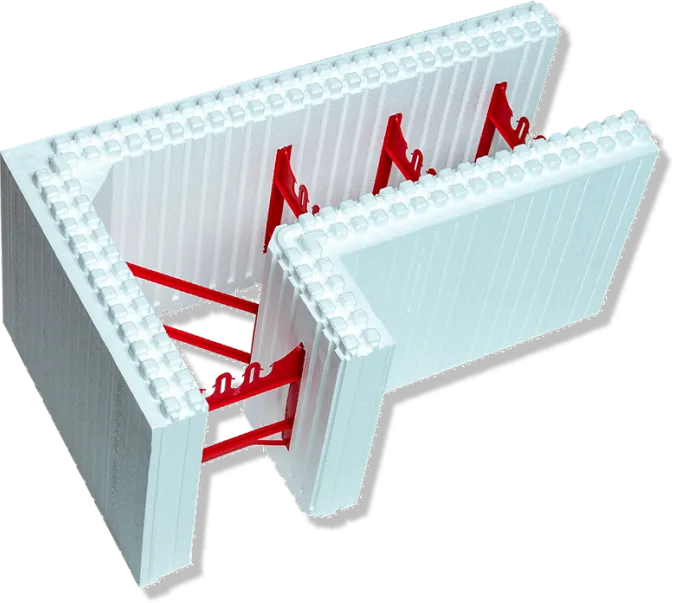

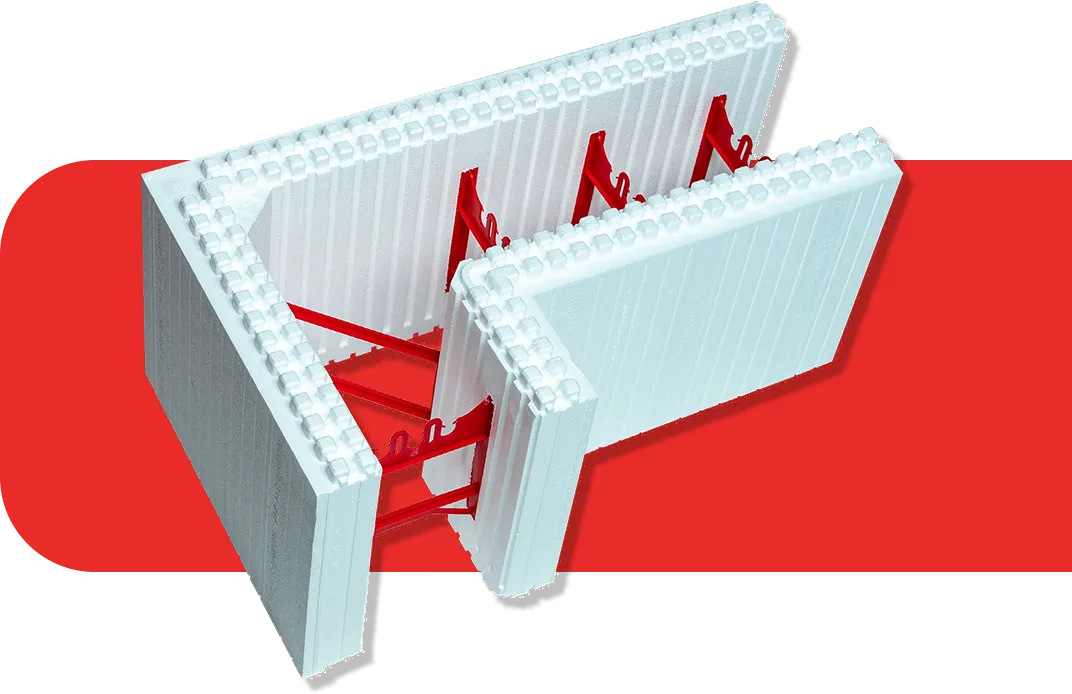

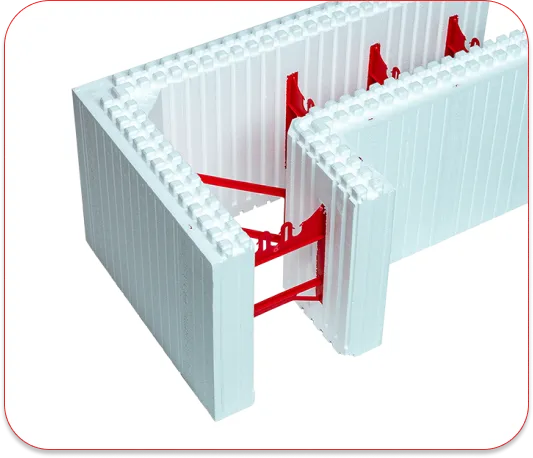

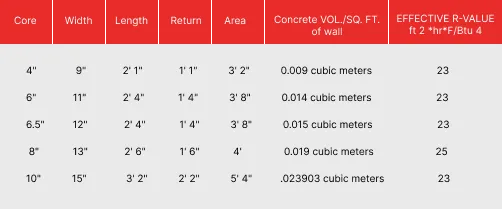

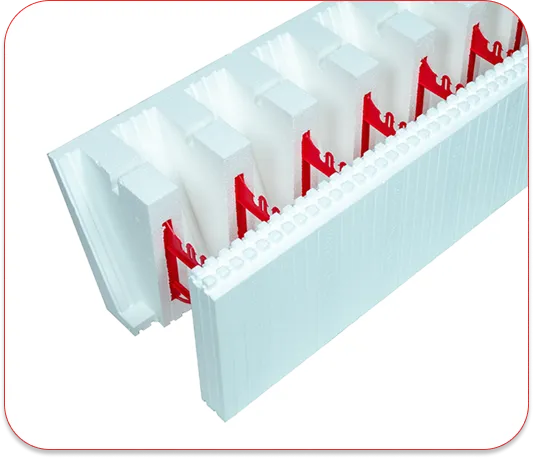

Insulated Concrete

Forms (ICF)

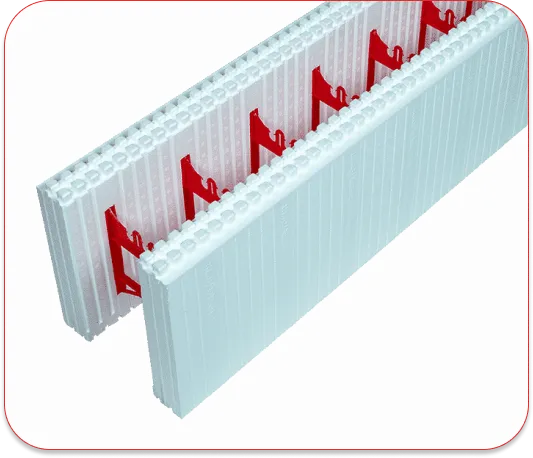

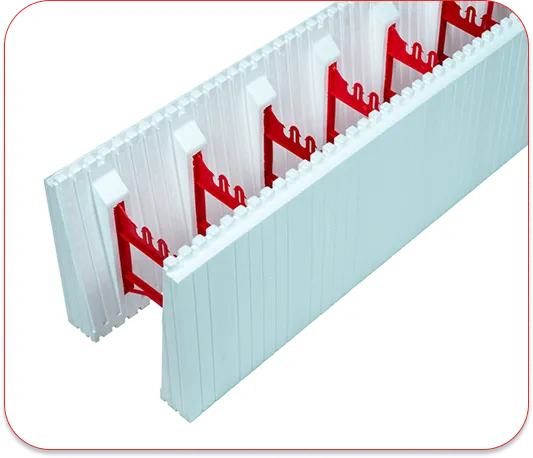

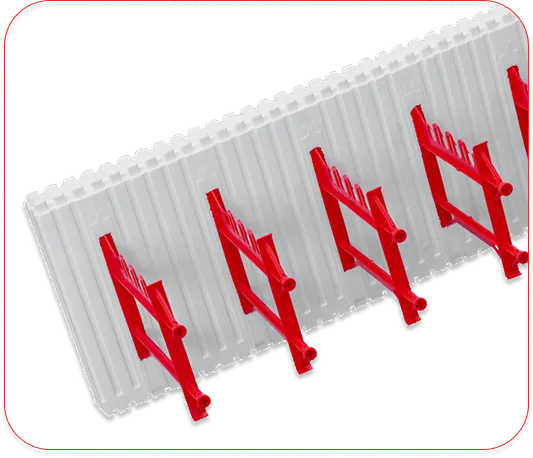

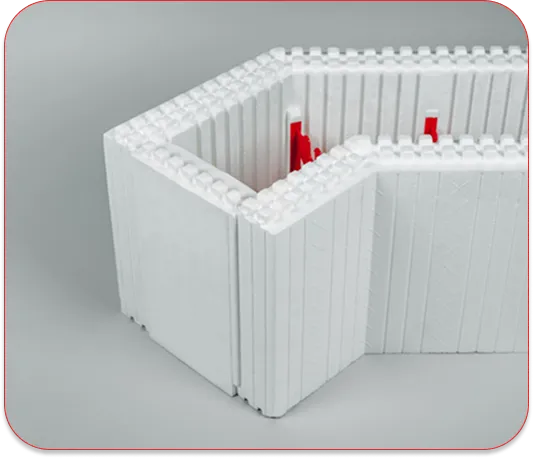

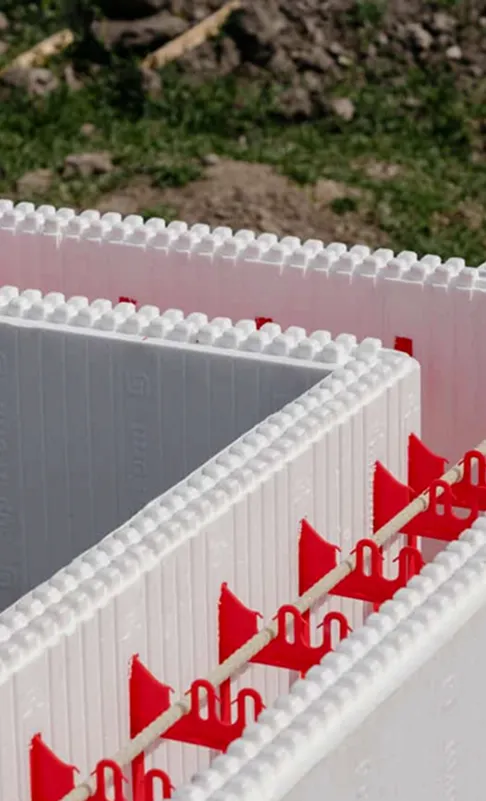

When builders want the best insulated concrete form, they turn to SuperForm. Featuring our distinctive red ties, our ICFs streamline construction, making projects quicker and easier. Our ICF system also allows for greater design flexibility. These forms are efficient, providing superior insulation and durability for your building projects.

Our unique square knob design offers 35% more surface friction fit than other systems on the market. The horizontal connection is so tight there is absolutely no vertical joint spreading.

The SuperForm tie stands tall with outstanding performance when compared to other systems. Our thick red tie flange (7.25mm – 5/16th) every 6”, are made of virgin polypropylene resulting in a higher more consistent tensile strength. You can have confidence that whatever you fasten to them will be secure. Our flow through design allows concrete to easily flow and bond to all EPS surfaces.

Our 6” tie spacing provides up to 33% more tie per block resulting in one of the strongest blocks on the market. With only 4” of foam between ties and 2” of foam on the end of the block, this eliminates vertical or horizontal bulging along block planes and provides a flatter, straighter, and stronger wall. The 6” inch tie spacing also allows for more attachment points in your wall, giving you more options.

Our grooved inside panel is designed for better concrete adherence. Our panels lock the concrete and EPS together making a connection that will not separate. The built-in anti-lift technology, locking all blocks down by concrete pressure on it. This eliminates the need to tie or lock down each row, making your installation faster.

SuperForm ICFs are designed with maximum design freedom with a 1″ repeating cut lines. This allows you to match any plan on the jobsite and helps reduce waste.

Our standard sizing of 4’ long x 1’ high makes building and estimating extremely simple. Our light weight block is very easy to handle by yourself, making it easier to work in trenches or up on the scaffolding. The 12” block takes out all vertical bulging in the wall giving you a flatter wall and gives you mores rebar options at 12” centers if needed.

Our newly updated corner tie and bracket mitigates one of the biggest challenges ICF installers face: corner blowouts.

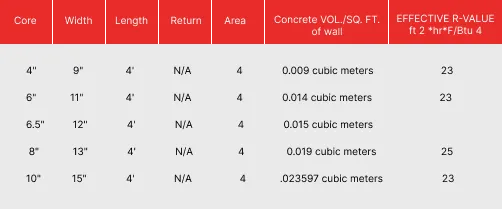

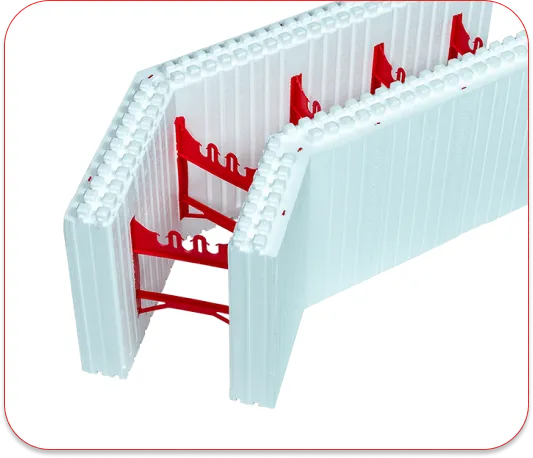

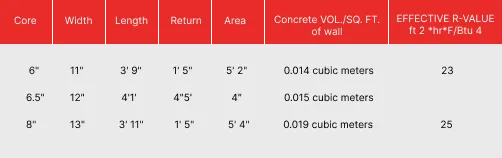

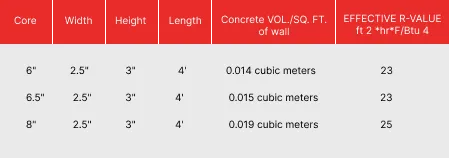

Meet the SuperForm ICF Block Series

Standard

Allows you to build straight walls with added durability and strength.

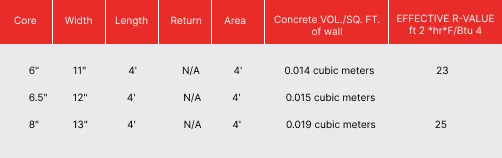

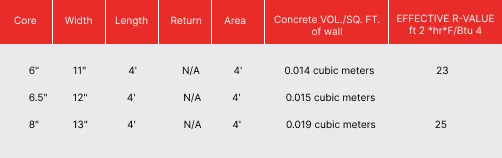

PRODUCT DIMENSION

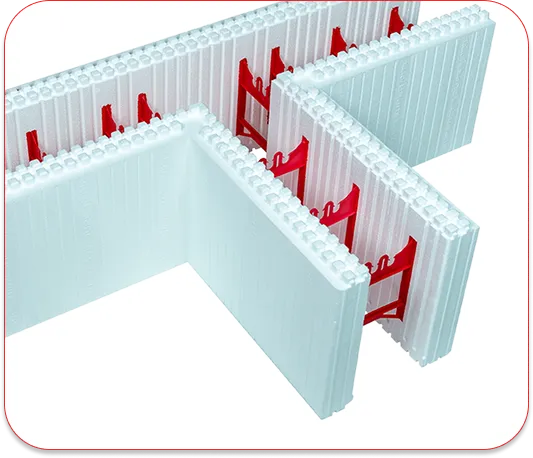

90 Degree

Creates strong 90-degree corners with minimal time required and greater ease, accompanied by an extremely strong corner tie with multiple fastening areas for finishing.

PRODUCT DIMENSION

45 Degree

Creates strong 45-degree corners with minimal time required and greater ease, with multiple fastening areas for finishing.

PRODUCT DIMENSION

Brick Ledge

Supports the installation of brick veneer on above-grade walls.

PRODUCT DIMENSION

Top Block

Provides maximum bearing surface at the top of your wall.

PRODUCT DIMENSION

T Block

Creates a T corner, eliminating the need for additional support or adjustments.

PRODUCT DIMENSION

Height Adjuster

Allows contractors to adjust the height of builds in small increments with minimal waste.

PRODUCT DIMENSION

One-Sided ICF

Ideal for various applications: commercial jobs requiring above-grade exterior concrete without parging, interior garage, and shop walls eliminating the need for covered insulation, retaining walls, elevator shafts, butcher/smokehouses, and more.

PRODUCT DIMENSION

End Buck

Can quickly slide into place to serve as an insulated buck or to terminate a wall.

PRODUCT DIMENSION

Why do these SuperForm ICF block features matter?

It maximizes builders’ budgets and time during ICF installation, as minimal accessories are required due to the unmatched strength of SuperForm.

While other systems require zip ties, wire ties, glue/spray foam, FormLock, kickers, or even applying plywood to every corner, SuperForm maximizes your budget without these extras. This also results in a faster and simpler ICF installation system.

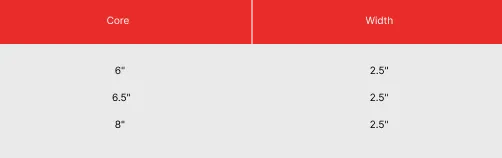

SuperForm offers a range of insulation products. Our EPS+ is a high-grade expanded polystyrene insulation. We also have our SuperForm Max+. It is a form of graphite polystyrene insulation. Both are cost-effective, durable, and sustainable.

Beyond these products, SuperForm has an array of accessories for insulated concrete forms. You can contact our team to learn more about our building products.

The Benefits of SuperForm Products

MST-BAR® Fiberglass Rebar

Learn how MST-BAR is a preferred and more durable solution for reinforcing concrete structures over steel and other fiberglass rebars.

Improving Construction With SuperForm MST-BAR

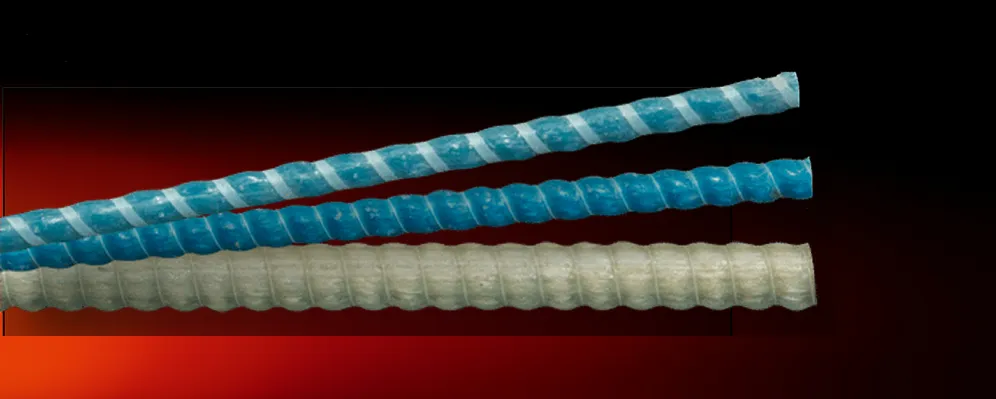

Introducing MST-BAR, a fiberglass rebar for use with SuperForm ICF. The glass fiber reinforced polymer (GFRP) material offers better tensile strength while being lighter than traditional steel rebar. With its unique properties and innovative design, it is redefining the standards for reinforcement in ICF blocks.

Stronger

& Lighter

Our MST-BAR is changing the construction industry with its combination of strength and lightweight design. The GFRP material makes it much lighter than steel rebar, but it boasts a higher tensile strength. These features allow it to outperform traditional steel rebar in several ways.

With its impressive lightweight design, MST-BAR opens many possibilities for designers and builders. It is easier for workers to handle to help speed construction projects. However, you are not sacrificing strength when you go with this fiberglass rebar. It can handle the same construction applications while being easier to use and reducing costs.

Superior

Design

The unique design of SuperForm’s rebar sets it apart from the competition. It's the only GFRP rebar featuring an integrally ribbed maximum strength design. This ribbed structure enhances its bond with concrete, reducing the risk of cracks.

It not only improves the structural integrity of blocks; it also allows for greater efficiency. Builders can also avoid up to 50% of traditional bent-bar applications using straight lengths of SuperForm MST-BAR.

We engineered our MST-BAR to be stronger, more reliable, and more cost-effective, setting new standards for performance and design.

Enhancing Performance

Being stronger and lighter are just two of the reasons builders choose MST-BAR for reinforcing concrete blocks. The GFRP material and its innovative design improve performance in several ways.

MST-BAR forms stronger bonds with concrete, enhancing structural integrity and reducing the risk of cracks. It offers greater fatigue resistance, ensuring it can withstand more stress and provide enduring reinforcement.

Sustainable

Choice

MST-BAR is more than just a superior building product – it’s also more sustainable than the alternatives. The production of this fiberglass rebar results in lower carbon emissions than steel rebar. That means it has a lighter environmental footprint.

By choosing MST-BAR, you're not only building with strength and reliability, but you're also contributing to an eco-friendly future. It's the ideal reinforcement for builders who value sustainability as much as performance

Why should I use MST-BAR for reinforcing concrete structures?

MST-Rebar is a fiberglass rebar that is specifically engineered and designed with an Integral Rib that mechanically locks it into concrete.

Unlike every other rebar, including traditional steel rebar and other fiberglass rebars, the only way to pull it out of the concrete is to break the concrete itself.

No other glass fiber reinforced polymer (GFRP) rebar, and certainly not steel rebar, can compete with MST-BAR's:

3x bond strength

3x tensile strength

20x fatigue resistance

MST-BAR is a more durable solution to concrete reinforcement.

Why do builders and contractors prefer it over steel rebar?

Builders and contractors are discovering the labor savings that come with the use of MST-BAR fiberglass rebar.Specifically, MST-BAR is

4x lighter than steel

MST-Bar allows workers to install rebar with ease and reduce workplace injury.

Saving labor reduces the time builders and contractors are on each job site. The installation of MST-BAR fiberglass rebar:

Takes half the time to install with half the number of workers

Requires ZERO maintenance and repairs

Builders experience an increase in productivity with MST-BAR, allowing them to achieve more projects in a month or the same amount of projects.

What are the other benefits of MST-BAR over steel rebar?

Other benefits of MST-BAR over traditional steel rebar include

Non Corrosive (suited to any environmental exposure)

Non Conductive (does NOT conduct heat, cold, or electricity)

Easy to Transport (75% lighter than steel, saving on shipping costs)

Easy to Cut (especially when using a diamond blade)

Benefits of MST-BAR

1/4 The Weight of Steel

Get 4x the product on your trucks and save on transportation costs.

MST-BAR is also significantly easier to handle and use.

3x Stronger Than Steel

With a tensile strength of 3x the amount of steel and a fatigue resistance of

20x the amount of steel, MST-BAR is the trusted solution for any project.

Greener Solutions

The manufacturing process of MST-BAR produces far less carbon emissions than the steel industry, which has a devastating impact on the environment. MST-BAR can be ordered to exact sizes, so it is manufactured to that size with no cutting or waste.

Lifespan of +100 Years

MST-BAR will never corrode, which can lead to spalls in the concrete. While steel

has a lifespan of 50 years, MST-BAR will outlast the concrete it is reinforcing.

Non-Corrosive &

Non-Conductive

MST-BAR is non-corrosive and suited to any environmental exposure.

MST-BAR does not conduct heat, cold, or electricity.

Superior Bond Strength

Our rebar delivers a bond strength to concrete 3x the amount as steel.

The only way to pull out the bar is to break the concrete.

Our Process

25% Upon Order Downpayment

75% Upon Delivery

Ready to start

your next project?